Why Is Outdoor Wire Cheaper Than Indoor Wire?

Outdoor wire is generally cheaper than indoor wire because it is manufactured using more cost-effective materials, less stringent insulation standards, and a simpler design. Contrary to what many might assume, outdoor wire does not necessarily require more expensive materials. Instead, the primary focus is on durability rather than aesthetics or flexibility, which are essential for indoor applications. This article will explore the reasons behind the pricing differences between indoor and outdoor wiring, the material and insulation variations, and which type is more appropriate depending on your specific wiring needs.

What Are the Differences Between Indoor and Outdoor Wire?

To understand the price difference, it’s crucial to first grasp the core distinctions between indoor and outdoor wiring. While they might serve similar electrical purposes, these wires are engineered with very different characteristics to cater to their respective environments.

What Is Indoor Wire?

Indoor wire is typically designed to be used within enclosed spaces, such as homes, offices, and commercial buildings. It is manufactured with a focus on safety, flexibility, and aesthetic compatibility. Due to stringent fire resistance and safety regulations, indoor wiring is often coated with a thicker layer of thermoplastic or other non-conductive material to minimize risks of electrical hazards.

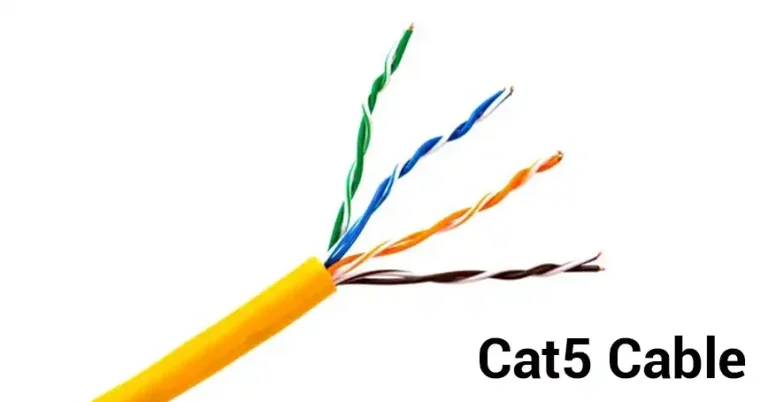

Common types of indoor wires include NM (Non-Metallic) and THHN (Thermoplastic High Heat-resistant Nylon-coated) cables. These wires are typically used for outlets, lighting circuits, and general-purpose applications within the home.

Characteristics of Indoor Wire:

- Insulation: Usually has multiple layers of insulation for enhanced safety and fire resistance.

- Flexibility: Made to be more flexible to navigate through walls and tight spaces.

- Appearance: Often has a smoother finish and more neutral colors to blend in with interiors.

Average Cost: Indoor wiring typically costs around $0.50 to $1.50 per foot, depending on the gauge, insulation type, and specific use case.

What Is Outdoor Wire?

Outdoor wire is primarily designed for durability and resistance to external elements like moisture, UV rays, temperature fluctuations, and physical impact. While the wire may have a simpler insulation coating, it’s typically made from hardier materials, such as polyethylene (PE) or PVC, that can withstand the elements. Despite this durability, outdoor wires do not require the same level of fire resistance and flexibility as indoor wires, which contributes to their lower production cost.

Common outdoor wires include UF (Underground Feeder) cables, Direct Burial cables, and Outdoor-rated Romex® wire, used for various purposes such as outdoor lighting, running power to sheds or garages, and more.

Characteristics of Outdoor Wire:

- Insulation: Usually a single but thick layer of UV-resistant and waterproof material.

- Durability: Designed to withstand harsh environmental conditions.

- Rigidity: Often less flexible compared to indoor wire, making it harder to maneuver in tight spaces.

Average Cost: Outdoor wiring usually costs around $0.30 to $1.00 per foot, depending on the gauge and specific outdoor rating.

Why Is Outdoor Wire Cheaper Than Indoor Wire?

1. Type of Insulation

The type of insulation is one of the key factors in the price disparity. Indoor wires are often insulated with multiple layers of high-grade materials, such as nylon, thermoplastic, or flame-retardant sheathing. This ensures enhanced safety against fire hazards, which is crucial for wires used within closed spaces where heat buildup and fire risks are higher.

In contrast, outdoor wire typically uses a single layer of polyethylene (PE) or PVC, which, while being UV-resistant and waterproof, is less costly to produce compared to the advanced insulations required for indoor wires.

Example of Cost Impact:

- THHN Indoor Wire: Uses two layers of insulation—one for protection against physical damage and another for heat resistance, making it more expensive at $1.00 to $1.50 per foot.

- UF Outdoor Wire: Uses a single robust coating that provides weather resistance, making it less expensive at $0.30 to $0.70 per foot.

2. Manufacturing Complexity

Manufacturing complexity is another reason why indoor wire is more expensive. Indoor wire must comply with multiple safety codes and regulations, especially regarding flame resistance and heat dissipation. This results in a more complicated production process with additional steps for testing and certification.

In contrast, outdoor wire manufacturing focuses more on durability rather than flexibility or aesthetic considerations, allowing manufacturers to produce it at a lower cost.

Manufacturing Cost Comparison:

- Indoor Wire: Often requires multiple layers, higher quality control, and testing for fire safety, increasing production costs.

- Outdoor Wire: Simpler manufacturing process with a focus on external durability, reducing overall costs.

3. Aesthetic and Flexibility Requirements

Indoor wire is designed to be flexible and aesthetically neutral, making it easier to install in tight spaces without causing damage to walls or fixtures. This requires more sophisticated materials and manufacturing techniques. On the other hand, outdoor wires, which are usually buried underground or installed along external surfaces, do not need to look appealing or be as flexible. The reduced emphasis on these features makes outdoor wire cheaper.

Material Cost Analysis:

- Indoor Wire: Requires materials that enhance flexibility and appearance, such as a smoother thermoplastic sheathing.

- Outdoor Wire: Uses rigid, durable materials like PVC or PE, which are easier and cheaper to produce.

Which Type of Wire Should You Choose?

Choosing between indoor and outdoor wire depends on the specific application. While outdoor wire may be cheaper, it is not always suitable for indoor use due to its lack of fire resistance. Likewise, using indoor wire for external applications could lead to damage from moisture and UV exposure, which could result in electrical failures or safety hazards.

When Should You Use Indoor Wire?

- Within residential or commercial buildings.

- For circuits that require fire and heat resistance.

- For applications that require a smooth and flexible wire for easier routing.

When Should You Use Outdoor Wire?

- For outdoor lighting or power extensions.

- For underground wiring or exposed external surfaces.

- When you need a budget-friendly option that prioritizes durability over aesthetics.

Wrapping Up

The primary reason outdoor wire is often cheaper than indoor wire comes down to insulation, manufacturing complexity, and material costs. Indoor wires need to meet stringent safety standards, making them more expensive, whereas outdoor wires are designed for durability, reducing production costs. When choosing between the two, always consider the safety and specific requirements of your project to ensure you pick the appropriate wire type.