Loose Tube Vs Ribbon Fiber

Optical fiber cables are essential in modern data transmission, powering applications from telecommunications to internet infrastructure. Within fiber-optic technology, loose tube and ribbon fiber are two primary cable structures that have distinct advantages depending on deployment needs.

In this article, we’ll break down the main differences, applications, and benefits of each type, and include tables for easy comparison.

What Is a Loose Tube Fiber?

Loose tube fiber cables are characterized by fiber strands enclosed within a protective tube, with space (or “loose” buffer) surrounding them. This construction allows the fibers to move independently within the tube, providing flexibility and protection against temperature changes and environmental conditions.

Typically, these cables are designed for outdoor use, as the loose tube construction shields the fibers from external stresses.

What Are the Advantages of Loose Tube Fiber?

The key advantages of loose tube fibers are as follows:

Water Blocking: Many loose tube cables have water-blocking compounds to protect against moisture ingress.

Temperature Resistance: The loose design allows the fibers to expand and contract within the tube, preventing damage from temperature fluctuations.

Suitable for Outdoor Use: The durability of loose tube fiber cables makes them ideal for outdoor applications like long-haul and metropolitan area networks.

Cost-Effective for Low-Density Applications: Loose tube designs are typically more affordable than ribbon fibers for lower-density fiber counts, making them a preferred choice for projects where fiber count is less crucial.

What Are the Disadvantages of Loose Tube Fiber?

Although not many, loose tube fibers do have a few drawbacks. They are:

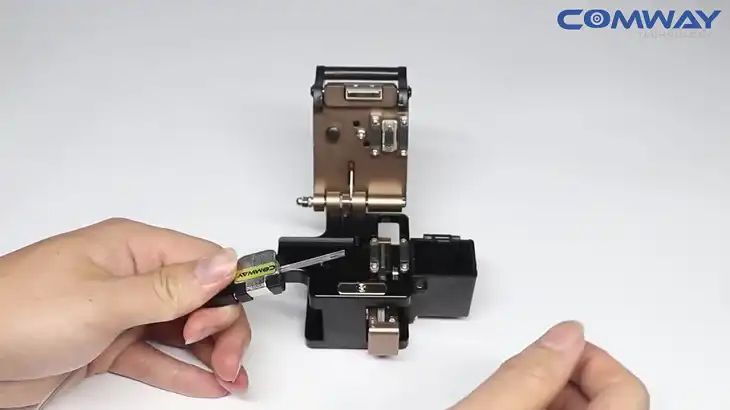

Time-Consuming Splicing: Since fibers are arranged in separate buffer tubes, splicing can be labor-intensive and time-consuming.

Limited Space Efficiency: Loose tube cables generally cannot match the density of ribbon fiber cables, which may require more space in high-fiber installations.

What Is Ribbon Fiber?

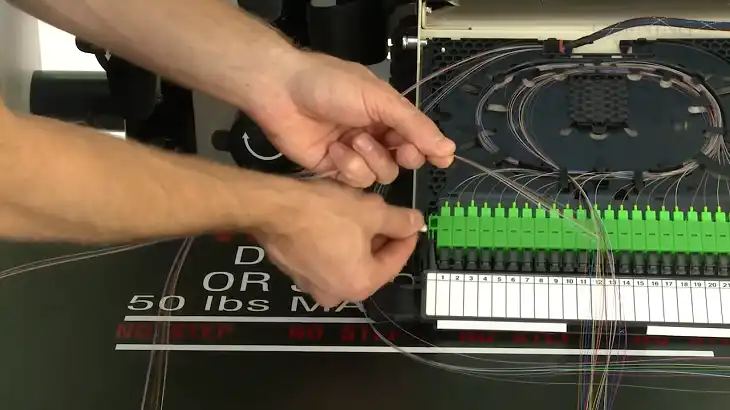

Ribbon fiber cables consist of individual fibers bonded together in a flat, ribbon-like structure. This setup allows for high-density packaging, making it suitable for data centers and places with limited space. Ribbon fibers can be spliced in groups, which greatly reduces splicing time and lowers overall deployment costs, especially for applications needing multiple fiber splices.

What Are the Advantages of Ribbon Fiber?

Below are the advantages of ribbon fibers:

Bonded Fiber Ribbons: Fibers are bonded side-by-side into ribbons, enabling easy mass fusion splicing.

Compact Design: Ribbon cables are more compact and typically have a higher fiber count per unit volume, making them ideal for high-density installations.

Ease of Splicing: Ribbon cables allow for mass fusion splicing, which enables technicians to splice multiple fibers simultaneously, drastically reducing installation time.

High-Density Applications: Ribbon cables are ideal for scenarios requiring high fiber counts in limited space, such as data centers and dense metropolitan networks.

Faster Installation: With the ability to splice 12 fibers at once, ribbon cables reduce splicing time, leading to faster deployment.

Space Efficiency: Ribbon fiber design allows for a more compact cable that can fit into smaller spaces, which is particularly valuable in environments with limited conduit space.

What Are the Disadvantages of Ribbon Fiber?

Challenges with loose ribbon fibers include:

Higher Initial Cost: Ribbon cables are typically more expensive due to their high-density and splicing-friendly design.

Less Flexibility: Ribbon cables are more rigid than loose tube cables, making them less suitable for applications that require frequent bending or in areas with high levels of environmental stress.

Sensitivity to Environmental Factors: Without the loose structure of a buffer tube, ribbon cables can be more susceptible to temperature and mechanical stress, making them more suitable for indoor or controlled environments.

What Is the Difference Between Ribbon Fiber and Loose Tube Fiber?

To illustrate the differences between loose tube and ribbon fiber cables, here’s a comparative table covering their physical characteristics, installation considerations, and performance.

| Feature | Loose Tube Fiber | Ribbon Fiber |

| Fiber Arrangement | Individual fibers in a loosely filled tube | Bonded fibers in flat ribbon bundles |

| Installation Speed | Slower due to individual splicing | Faster with mass fusion splicing of entire ribbons |

| Fiber Density | Moderate; fiber counts up to a few hundred (up to 288 fibers) | High; capable of fiber counts up to several thousands (up to 3,456 fibers or more) |

| Flexibility | Greater flexibility, withstands bending and flexing | Less flexible, more rigid due to bonded structure |

| Environmental Suitability | Ideal for outdoor and harsh environments | Primarily used in controlled, indoor environments |

| Splicing Complexity | Higher splicing time, requiring individual fiber splicing | Lower splicing time, can splice up to 12 fibers at once |

| Repair Complexity | More complex to repair due to individual fiber splicing | Easier to repair in high-fiber-count settings |

| Cable Size | Larger diameter, with added strength elements | Compact, thinner profile due to high packing density |

| Water Resistance | Often gel-filled for water blocking | Typically dry or with water-blocking tapes |

| Cost | Lower material cost, higher labor cost | Higher material cost, lower labor cost |

Frequently Asked Questions

Can you ribbonize loose tube fiber?

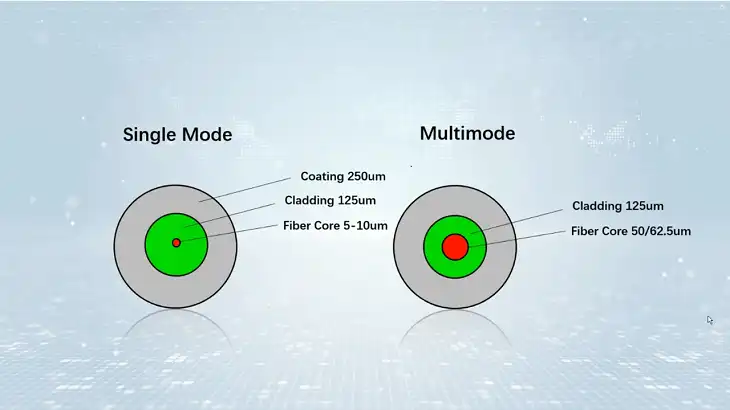

As long as the fibers are the same type and size, like Singlemode 8/125um or Multimode 50/125um, you can connect loose tube fiber to ribbon fiber cables.

What size is loose tube fiber?

A 144 fiber loose tube cable is usually 15-16 mm in diameter.

In which application would you not normally use loose tube fiber?

Loose tube fiber might not be the best choice for applications requiring extremely high fiber densities or very long distances. Ribbon fiber or specialized fiber types might be more suitable in these cases.

Conclusion

In summary, the choice between loose tube and ribbon fiber will depend on your deployment environment, budget, and project requirements. Loose tube fiber offers a more durable solution for outdoor use, while ribbon fiber provides efficient, high-density solutions for indoor and high-fiber-count applications.

By examining the specific strengths and trade-offs associated with each type, you can optimize their fiber optic networks to meet both performance goals and budget constraints.